So yeah.. it has been a long time since I've posted much. Life has been full. Today, I will just close the loop on the carb deep cleaning and re-gasketing. I will try to get back here relatively soon with some other goings on. I thought I posted this update last Fall when it happened, but I clearly didn't.

Just a reminder, Oliver (1978 MGB) has a SK Racing or OER Racing side-draft carburetor. These look very much like the DCOE Weber and even can use some of the jets from a Weber. The accelerator pump and float level can be adjusted from the outside and the main jets can be accessed through a cover on the top. So, very few of the changes one usually makes to a carb requires the carb to be removed from the engine. The inlet pattern matches the Weber DCOE, so you can use a more readily available intake from Weber. Even the 4 bolts on the bottom are the same so you can use a Weber-intended heat shield like I did. Curious about getting one? Here is a source in Japan (these are a go-to carb among Nissan/Datsun enthusiasts I am told). Those who have them rave about them. Except me, so far. I hope to be among the celebrating majority soon.

Almost a Test Start

Setting the stage, I had a crisp fall day to take a look at Oliver, the 1978 MGB. I wanted to see if the carb work was the winner for his bogging down when I hit the accelerator pedal. I pulled his cover off, hooked up the battery and added some fresh fuel. I had pumped the tank dry when I removed the carb; not sure if I mentioned that last time. Anyway, I turned the key to run. I got the satisfying sound of the fuel pump running and then that not-so-satisfying gasoline smell. I went around to the right fender and could see fuel shooting out towards the radiator. Eeek. I turned off the key and then spotted a failing fuel hose. After a brief rummage through some boxes in the "tool shed" I found some suitable hose and had the system buttoned back up relatively quickly. This is as good a time as any to remind all my fellow old-car owners to replace your fuel hoses.

With the new hose in place, I returned to the driver seat, turned the key to run and waited for the fuel pump sound to change, letting me know that it had established pressure. With the earlier fuel line failure, the smell of gas was still present, so I walked around to the front to inspect for leaks. Nope. So, I turned the key to run and he started pretty fast. It was rough, but I could keep him idling at the carb by pulling on the accelerator cable.

Fiddling with it

I focused first on getting the idle jets set. I followed the basic set-up rule of turn all the way in, then back out 2 turns when I did the reassemble. In theory, you should be close at that point. I did not notice much difference when I moved the screws in and out more than 1/2 a turn. I think I eventually settled on them being out just past 2 turns. I expect when fully warmed up and in an expert tuner's hands a different setting will be found.

Then I shifted to the idle speed screw. Doing this on your own without a hand-held tach is kind of comical. You walk to the driver door and look at the tach. Note the speed and if it needs to be faster, go to the carb and adjust. Then walk back and see if you hit your target. If not, wash-rinse-repeat. I am sure there are much more experienced mechs out there who can hear the right speed or have a hand-held tool so you aren't getting your day's steps in 2 steps at a time like that.

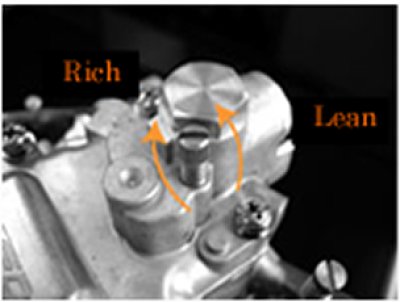

Last, I wanted to see if I had solved the bog-on-accelerate. So, I yanked on the accelerator cable at the carb and.. bog. Sadness. In my time during the rebuild, I spent more time looking at the exploded diagram than I had before. I remembered there was an accelerator circuit, and located the screw on the top of the carb. In the image on the left, here, the screw is the big one on the furthest left, near the intake-side of the carb.

When I dismantled the carb, that screw was nutted all the way down snug. So, either the prior owner had torqued it down or I did at a time I don't remember. Regardless, I started loosening that screw (lefty-loosey) while I rev'd the engine. And the bog started to fall away. I was able to rev it fairly quickly without the engine starting to die on me. I stopped loosening it before I was able to yank on the cable as if I was going from foot-off-pedal to pedal-on-floor. I believe what had been happening was that the accelerator circuit had been flooding the engine with too much fuel when I pushed on it. Now, it was getting the right amount of fuel to account for the big burst of air from the opening of the butterfly without overcompensating. Looking back, this has probably been the issue all along and the cleaning/resealing may not have been necessary. In the end, I don't care, and cleaning the carb will only pay more dividends anyway.

Wrap Up

So, did I go for a test drive? No. Why? The brake bleed attempts that I have done since I replaced the master cylinder have not gotten the brake pedal predictable. Rather than have a spirited drive to celebrate, I waited for the tailpipe to cool down and put Oliver's cover back on (queue the sad trombone). One of the first things I will be doing this spring is another brake-bleed attempt. I may just hobble over to the local Firestone and have them do it. I just want to drive this guy now and his spongey brakes have been a blocker for too long.

Also on the list are changing the 12V source for the voltage gauge from the purple circuit which used to power the clock to the switched and fused green circuit. I have a few other odds and ends I need to complete before Oliver is "finished", the largest of which is replacing the body-to-windshield seal so he can be driven in rainy weather. There is always something with these old cars and I really wouldn't want it any other way.... so long as the something doesn't leave me stranded on the side of the road outside cell range.

Well, that's it for this time. Sorry it has been so long. Life gets busy and I have not been able to play with my cars much. I am working through the permitting process to get a garage built so there will be posts about that, and then playing on cars (and blogging about it) can return to a year-round sport. Thanks for tuning back in, and I hope to be more frequent in 2025-